These simple instructions will help you to build a very cost effective practice/training bow from easy to find materials. Building a PVC bow is quite simple and can be done by most people with only a few tools. This project is one that most people could complete in less than an hour. PVC pipe bows are a very simple way to get into archery and are a cheap practice option if you already are.

Warning: Children should be supervised at all times if allowed to use these bows as they are weapons and can cause serious injury if misused.

Warning: When using any tools be careful to use any necessary safety equipment and practice safe usage of the tools. Failing to do so can cause injury.

Step 1: Gather Materials

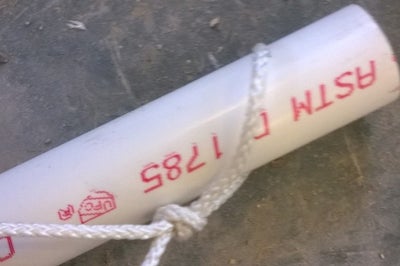

- About 6ft of 3/4 inch PVC pipe

- White schedule 40 pipe works well and is easily available

- A good length of thin high strength rope (more than 8ft and at least 50lb breaking strength)

- Polyester blend 550 paracord works if available

- Some tent lines are rated strong enough

- A few 5/16 in diameter fiberglass rods 4 feet long

- These are used in reinforcing the bow and are optional if making the standard bow

- These can be easily found at some hardware stores and are commonly used in lawn reflectors

- A few wooden dowels around 1/4 - 3/8 in diameter

- This is only if you wish to make your own arrows

- Look for straight grain along the length of the dowel

- Duct tape or other strong tape

Tools list:

- Something to cut PVC such as a hacksaw

- Something to cut dowels if you wish to make your own arrows

- A knife

- Measuring tape

Step 2: Prepare the Pipe

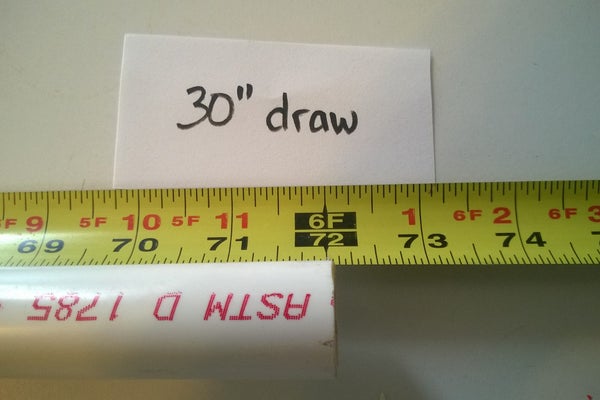

- The first thing that you need to do is to determine your bow's desired length.

- One way to do this is to first determine your draw length. Hold your arms out perpendicular to the ground and measure from fingertip to fingertip dividing that distance by 2.5. Then refer to a chart similar to the one here.

- Another way is to simply make the bow roughly twice your draw length calculated in the same way. This produces a slightly shorter bow than in the chart.

Note: The longer you make the pipe the lighter the draw weight will be, due to material limitations, so you can shorten the bow's length if you wish to keep a higher draw weight. Your bow's length does not have to follow either guideline listed above.

- Now that you have your desired length, cut the PVC pipe to length adding about 2 inches to the bow length you just found.

- Now that the pipe is cut to length, measure in 1 inch from both ends and make a mark.

- Now cut a shallow slot just deep enough for the string to slot into firmly on the marks.

- Cutting just deep enough to make it through the outer wall of the pipe is roughly deep enough.

- Make the cut slightly narrower than the rope when stretched slightly.

Warning: Take care when making these slots in making sure they are lined up as much as possible on the same side of the pipe as these will hold the string in place and keep it from sliding off the bow during use.

- Smooth the cuts you just made making sure to not widen it too much further. At this point the bow string at tension should snap into the slot with slight pressure.

Step 3: String the Bow

- Take the rope and tie a loop into one end just large enough to slip over the end of the pipe.

- Slip the loop over the pipe and seat it into the one of the slots.

- Hold the cord, still in the slot, along the length of the pipe.

- Tie another loop into the cord about 5-6 inches from the end opposite the one the cord is already slotted into and trim the excess cord.

Note: If you plan to reinforce the bow skip steps 5-6 for now - Now place the already seated end of the pipe on the ground so that the pipe runs at an angle behind you and the end is under or slightly ahead of you.

- Using your leg as a pivot, bend the top of the pipe from behind you forwards until it is curved and slip the second loop over the end slotting it into the second slot.

- Check the bridge height.

- From the center of the strung bow measure from the pipe to the string.

- If this length isn't around 6-8 inches, adjust the loop position to shorten or lengthen the string adjusting the bridge height.

- Use a lighter to singe the ends of the string so that it cannot fray as easily.

Warning: Keep a firm handle on the pipe as it can snap back and hit you if it slips.

Step 4: Reinforce the Bow

Note: This step is optional but recommended as it will strengthen the bow and increase the draw weight.

- Measure out four lengths decreasing lengths of fiberglass rods.

- For bows around 5ft lengths of 12,18,30,36in work well

- For bows around 6ft lengths of 4,3,2,1ft work well

- Feel free to modify the lengths as long as you get 4 rods in decreasing lengths

- Cut the four rods to the determined lengths.

Warning: Cut fiberglass will cause discomfort or irritation if it comes in contact with the skin. Wear protective clothing and cut a well ventilated area to help keep the dust and shavings away from yourself. - Mark the very center of each of the cut rods.

- Use the tape to secure the four rods together in a bundle.

- Make sure that the center marks are all aligned together.

- The bundle should be wrapped tightly in tape but adding only minimal thickness to the bundle with the tape.

- Insert the now wrapped bundle of rods into the pipe.

- If the bundle is loose add a little more tape to make the bundle snug in the pipe but not too tight that it becomes difficult to move in the pipe. The goal is to keep it from sliding in the pipe during use.

- Center the bundle in the pipe as closely as you can.

- Refer back to steps 5-6 of the "Stringing the Bow" section to string the bow for use.

Step 5: Make Arrows

Note: Bought arrows can be used as long as the nock will fit onto the string. Self made arrows can be an inexpensive alternative to the bought arrows that can be used for general practice.

- Determine the desired arrow length.

- You should make the arrow a few inches longer than your draw distance.

- Examine the ends. Find the one with the straightest grain for the longest distance.

- Cut the dowel to length cutting off of the opposite end as the one you just found to have the best grain.

- Cut the nock.

- Examine the end with the straightest grain for which way the grain runs.

- Cut a small groove in the end of the dowel perpendicular to the grain slightly thinner than the string.

- The string should be able to snap into the groove and stay in but be able to come out easily.

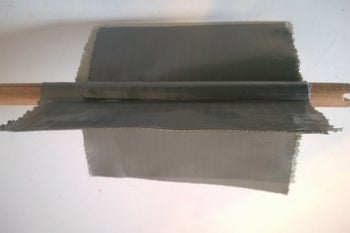

- Attach Fletching (Optional)

- Feather fletchings can be glued onto the arrow using a jig.

- A cheap method would be to use duct tape to simulate feathers.

- Attach a short strip of tape to the shaft.

- Attach another strip of tape across the shaft from the first.

- Fold it onto the first.

- Repeat for as many fletchings as desired.

- Trim the tape to a feather shape.

Warning: Duct tape feathers don't fold as well as real feathers so wear gloves when shooting as the tape can cut your hands when shooting.

- Attach arrowhead (Optional)

- For my general practice arrows I do not use tips I simply sharpen the point end with a knife.

- Glue-on tips can be found that can be attached after grinding the tip end it into a cone shape.

- Tips can also be made and glued into a notch in the tip end and then securing it with a thin string wrap.

Step 6: Wrapping Up

Congratulations you now have a finished PVC pipe bow. With this bow you will be able to practice your archery skills or learn some new ones. These bows are simple enough to make that they could very well come in handy in a survival situation.

When storing your bow you should unstring it to keep strain off of the pipe and the string. This will make it last longer.Over time the PVC will weaken and can break if stored in direct sunlight or is under strain so proper storage can be very useful in prolonging the life of a PVC bow. If you notice any cracks or deformities in the pipe over time do not use the bow as it can break during use and cause potential, though unlikely, injury. Simply replace your pipe if it starts to wear out.